Increase the welfare and profitability of your herd

Heat stress, Animal welfare, Milk production, Fertility, Health, Farm profitability, Ongoing support

Summer heat stress is considered one of the major causes of losses in the global dairy industry. In addition to significant losses in milk production, heat stress can reduce the conception rate of dairy cows by up to 30%, and its effects can last into winter, with progressive deterioration over the years. The consequences are known to all dairy farmers: if the barn is not adequately cooled, from summer to autumn there is a drop in intake, a drop in production, a drop in milk quality, a drop in reproductive performance and a drop in health status.

The S/W index was first used in Israel, with the fundamental contribution of Prof. Israel Flamenbaum, and has been used for many years as a management parameter integrated into the farm routine.

The Italian Breeders’ Association (A.I.A.) has recently adopted the Summer to Winter index (S/W INDEX), as a fundamental tool to evaluate the thermal stress of the farm.

In Israel, in 2017, the S/W Index on farms was:

0.98% in 23% of the stables

0.95% in 66% of farms

0.91% in 11% of the stables

In Italy the average S/W Index is about 0.85: this means that summer production is just 85% of winter production, which is equivalent to losses of tens of millions of euros.

Farms following the “ELEMENTS PROGRAM” achieve outstanding results with an S/W Index of 0.98, which translates into production losses of less than one litre of milk in the summer months and practically unchanged fertility throughout the year. For the farm, these results translate into tens, but more often hundreds of thousands of euros in additional annual revenue.

2. ANALYSIS OF THE BARN. Once the S/W index and the eventual economic loss linked to it have been calculated, the Elements Program provides for the actual analysis of the structures and cooling systems present in the farm and the analysis of the stable procedures.

3. PCORRECTIVE DESIGN The analysis leads to a third phase: the design of corrective measures (both structural/plant engineering (environmental settings, cooling systems, irrigation systems, lighting and windbreaks) and stable operating procedures (presence of animals, movements, times, methods of supplying fundamental elements: air, water, light).

4. OPERATIONAL PHASE: INSTALLATIONS AND PROCEDURES. After the presentation of an estimate and possible acceptance, we move on to the production of what was defined in the project phase: we therefore go on to the installation (or adaptation) of the cooling systems and the setting up of the stable operating procedures. The prerogative is to obtain an automated cooling management, with less work for the breeder, against a greater welfare of the farm and production efficiency.

5.TEMPERATURE MONITORING The temperature monitoring phase involves the insertion of vaginal data loggers on a representative sample of the herd (eight cows per group), in order to monitor the basal temperature of the cows. (In fact, there is strong scientific evidence that the productive and reproductive performance of cows is fully preserved when their core temperature is below 39.2°C. Action must therefore be taken to ensure that the animal maintains this value for as long as possible, ideally throughout the day). Temperature monitoring will enable the new stable settings to be verified and any necessary improvements to be made.

6. VERIFICATION OF RESULTS AND CONSTANT SUPPORT. At pre-defined intervals, Arienti technicians, together with the breeder, check the systems, monitor the conditions of the farm and follow the results, also in economic terms, providing short-, medium- and long-term data, for constant support, health and production security.

The study also focused on a group of 99 farms participating in the Element intensive cooling programme of Arienti, a manufacturer and installer of farm cooling systems.

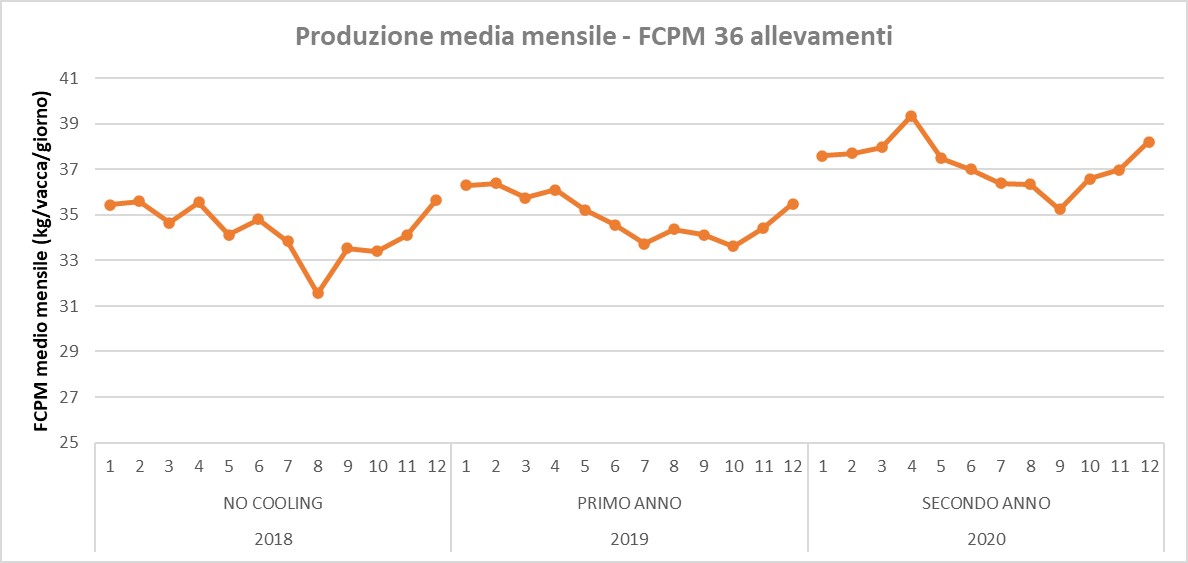

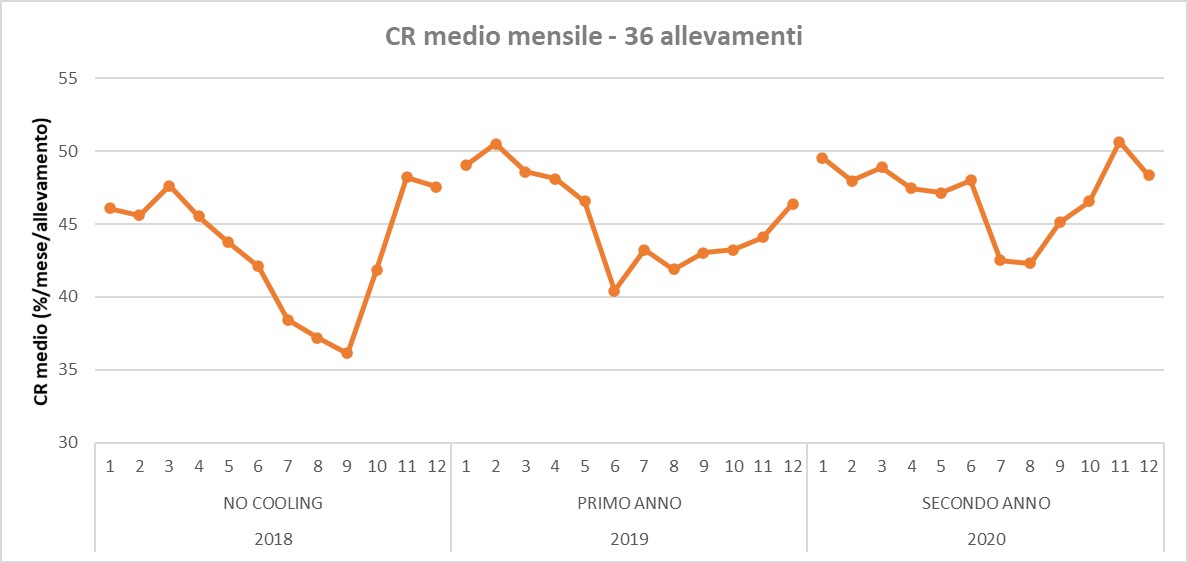

The monthly averages for the three years considered of the milk production and conception rate of the 36 farms that started the Arienti Element programme in 2019 are shown in Figure 1. The graphs describe how the performance of the cooled cows evolves over the three years considered.

Figura 1 – Monthly averages of (a) corrected milk (kg/cow/day) and (b) conception rate (%) on all registered inseminations.

From the data represented in figure (a), we can see a clear trend of continuous growth of the average production per cow. The average winter production per cow increases from 35 kg in the year before the start of intensive cooling to 38 kg and more in the summer of 2020, where cooling has been adequately provided for two consecutive summers. It can also be seen from the graph that the difference in production between summer and winter goes from 4-5 kg per day to 1-2 kg in the following years. As can be seen in figure (b) the conception rate gap in 2018 was 10 percentage points (going from 45% winter to 35% summer), while after two consecutive years of cooling the decrease is around 5% (going from 50% winter to 45% summer), i.e. half of the decrease compared to the year before the start of cooling, but above all achieving summer reproductive performance almost comparable to the winter performance in the pre-cooling period.

As can be seen from Table 2 and the two previous graphs, the improvements in production levels after the first summer of intensive cooling are less than those achieved in the second summer (about half of the improvement in the S:W index), while as far as reproduction is concerned, the improvement is already completely achieved in the first year.

The continuous improvement in summer milk production in the two years analysed can be attributed to the fact that the intensive cooling of the cows in summer helps them to eat more and, although they produce more, they are still able to accumulate more body reserves in the last phase of lactation and lose less in the first phase of the next lactation, especially when this transition phase takes place in summer. In this way, cows maintain a better body condition that positively influences both milk production and fertility in general, especially in the summer months. The improvement of CR already in the first year of intensive cooling has as an immediate consequence the decrease of the average calving distance (average DIM), with the consequent increase of the average farm production and the improvement of udder health.

Read the full article here: go to article.

RESULTS

Graphs of farms that have chosen the Elements Program

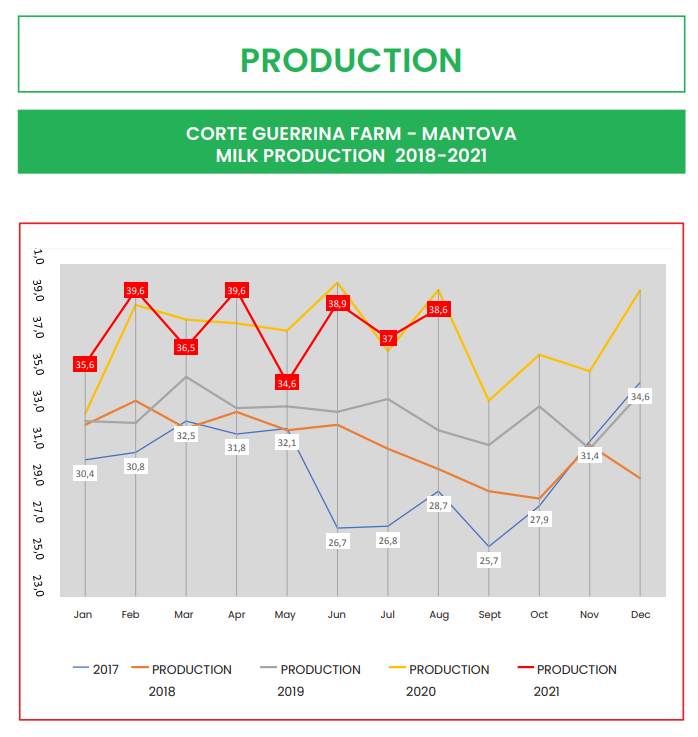

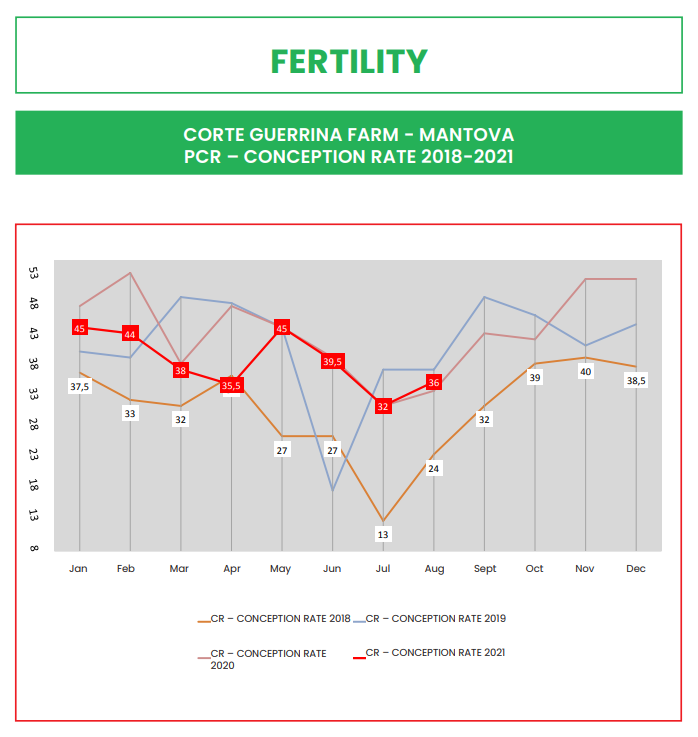

Corte Guerrina farm in Borgo Virgilio (MN).

The company of brothers Alberto and Giorgio installed the Elements- Arienti cooling system in 2018. Summer production has always been improving without interruption over the years. The S/W index has progressed enthusiastically to over 1.2 in 2020 and 2021, when summer production exceeded winter production. Fertility also doubled in the warm months compared to previous years. Congratulations to the Ettori brothers!

Corte Guerrina farm in Borgo Virgilio (MN).

The company of brothers Alberto and Giorgio installed the Elements- Arienti cooling system in 2018. Summer production has always been improving without interruption over the years. The S/W index has progressed enthusiastically to over 1.2 in 2020 and 2021, when summer production exceeded winter production. Fertility also doubled in the warm months compared to previous years. Congratulations to the Ettori brothers!

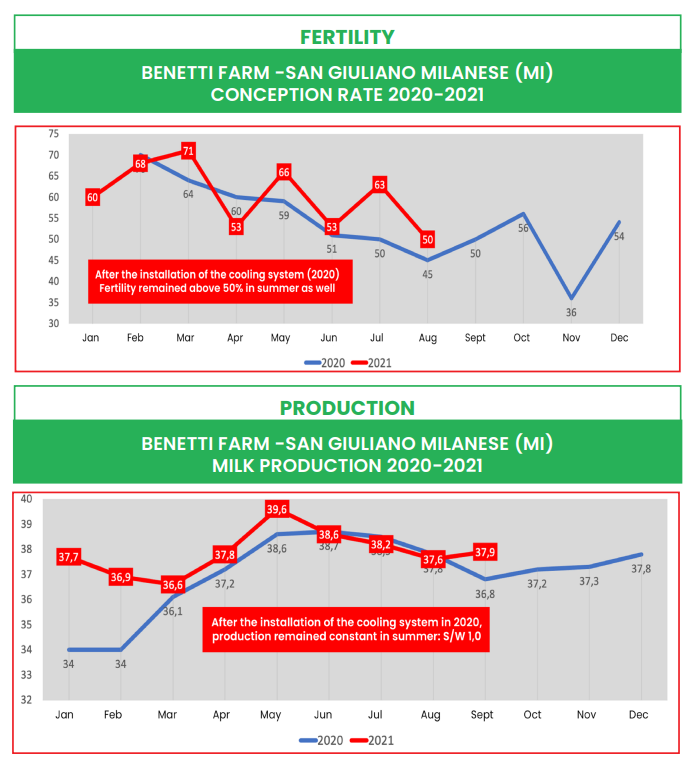

Benetti farm in San Giuliano Milanese

The Benetti farm with 250 milking cows is a successful example for us. The Elements-Arienti cooling system was completed in 2020 and production and fertility remained constant throughout the summer of 2020 and 2021. The SW Summer/Winter index for 2021 is over 1.0!

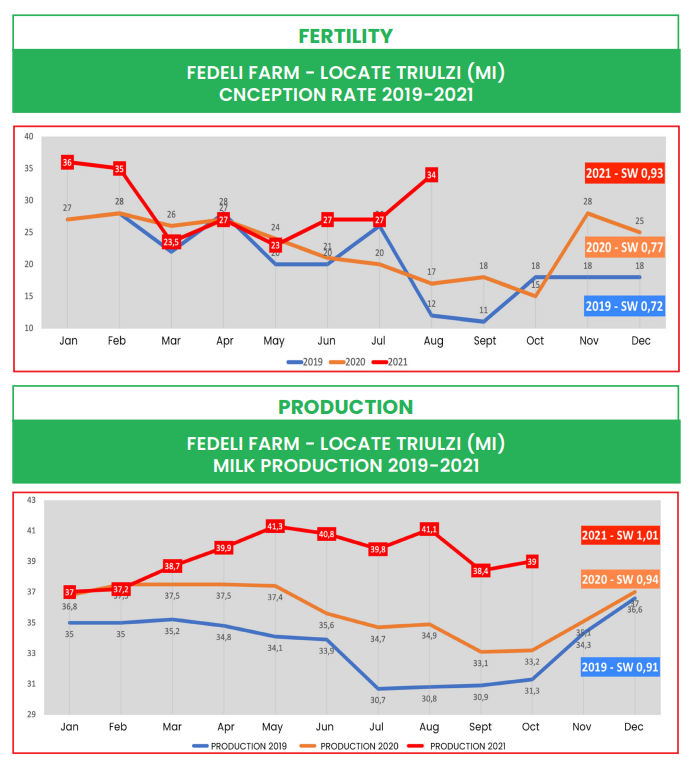

Fedeli Farm in Locate Triulzi (MI)

The Fedeli herd -540 cows with milking robot- confirms our best results. The milk production in the summer months, over 40 kg/head, exceeded the winter one, with an S/W Index of 1.01. Fertility also benefited from the Elements – Arienti cooling programme. In 2021 there is no difference between winter and summer fertility, a great result.

This is data. IMPOSSIBLE not to choose Program Elements.

WORD FROM A BREEDER

The Elements Program explained by a breeder who chose it

In July as in January

Giorgio De Cao explains: “Thanks to this cooling system my cows have much less problems with heat stress. As a result, we have more pregnancies in June, July and August, so the following spring we have more calvings. So the number of calvings becomes regular throughout the year and the lactation days are reduced to 165, which results in higher average milk yields. Without cooling, however, I would have 200-day lactations and therefore lower milk production.

And that’s not all, because the Mantua-based farmer adds: “Since my cows have more energy thanks to cooling, I have recorded fewer accidents, such as those linked to pubic diastasis. Furthermore, cooled cows spend less time standing and therefore more time resting, which as we know is a very productive activity”.

De Cao adopted this cooling system in 2019, starting with half of his barn. He then went on to equip the whole barn with it in 2020. “And since I have been using cooling in July, I am seeing an increase in production of around 10 quintals of milk compared to the July months before cooling”.

“In short, in July my cows offer the same milk production as in January. This increase in production fully repays the investment in this animal cooling system”.

The dairy farm run by Giorgio De Cao is part of the agricultural company F.lli De Cao s.s., located in Romanore di Borgoforte (MN). Giorgio De Cao is co-owner of the farm together with his cousins Sergio, Giovanni, Giuseppe and his father Bepi.

Read the full article here: go to the article.

Technical articles

Find out more on the main zootechnical publications

ZOOTECHNICAL INFORMER

AGRONOTITIZIE

Testimonials from Companies and Breeders

More than 200 farms have chosen Arienti’s Elements Program

Arienti | FREE advice

Promo valid until 15 March 2022.

Promo valid until 15 March 2022.